Next-Gen SCADA Systems: Transforming Data into Actionable Insights

Next-Gen SCADA systems have revolutionized the way industries monitor and control their operations. Schneider SCADA makes good control panels for different industries with advanced technology that is efficient and reliable. These systems eliminate the need for manual intervention, allowing organizations to streamline their processes and reduce operational costs.

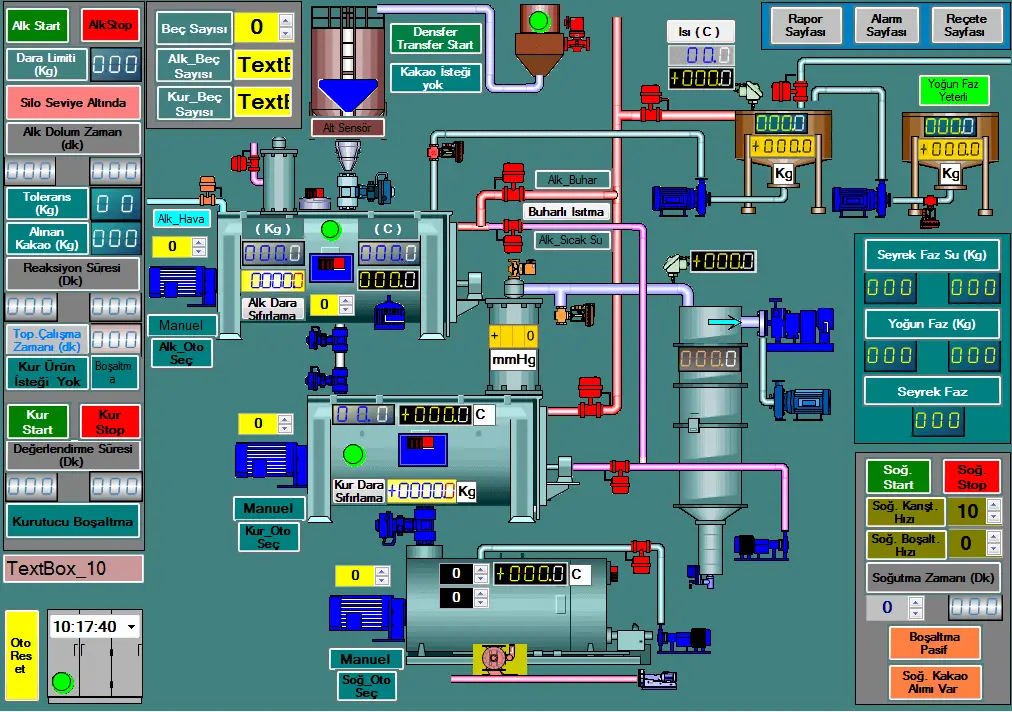

SCADA is easier for operators to use and understand, with user-friendly interfaces and real-time data. This not only enhances operational efficiency but also ensures timely decision-making for improved productivity.

The integration of Internet of Things (IoT) technology has further revolutionized Next-Gen SCADA, enabling seamless connectivity between various devices and systems. This integration allows for real-time data exchange, remote monitoring, and control of operations, no matter the geographical location.

Organizations have successfully integrated IoT into their Next-Gen SCADA Control Software. Sectors such as oil, gas, water treatment, and manufacturing utilize these systems. This has resulted in enhanced efficiency, proactive maintenance, and data-driven decision-making.

The ability to collect and analyse data from IoT devices has helped organizations enhance their operations. It has also enabled them to identify issues and implement effective solutions. As a result, overall performance has improved.

SCADA Systems Key Features and Innovations

Automation control panels installation is a crucial aspect of any SCADA Control System. A well-designed and properly installed control panel ensures seamless operation and efficient control of various processes. It withstands harsh environmental conditions and offers easy access to various components for maintenance and troubleshooting.

The HMI control panel’s design is important for user experience, allowing operators to monitor and control processes well. With intuitive interfaces and clear visualization, operators can quickly identify anomalies and make informed decisions.

Control panel fabrication is important for a SCADA success, along with installation. Quality fabrication ensures that the panels are built to meet specific requirements, including size, materials, and functionality. This process involves precision engineering, electrical wiring, and thorough testing to ensure optimal performance and reliability.

As technology advances, SCADA continue to evolve with innovative features. One such innovation is the integration of IoT, which allows for seamless connectivity between devices and sensors. Real-time data collection and analysis enable better decision-making and improved process optimization.

With the ability to monitor multiple devices and sensors simultaneously, operators can easily detect and address issues before they cause disruptions. Furthermore, the use of artificial intelligence (AI) in SCADA is becoming increasingly prevalent. AI algorithms can analyze vast amounts of data and identify patterns, anomalies, and potential risks.

This not only enhances the overall efficiency of the system but also facilitates predictive maintenance, reducing downtime and extending the lifespan of equipment. The integration of AI in SCADA holds immense potential for improving productivity, reducing costs, and enhancing operational performance.

Enhanced Cybersecurity Measures in SCADA Systems

Addressing security concerns in SCADA is of utmost importance in today’s digital landscape. With the increasing reliance on industrial remote monitoring and control systems, it becomes imperative to safeguard critical infrastructures from potential cyber threats.

SCADA systems play a crucial role in various industries, including industrial power distribution panels and integrated control and safety systems. Therefore, ensuring the security and integrity of these systems is paramount for smooth and safe operations.

To address security concerns in SCADA, several measures can be adopted. First and foremost, implementing robust access control mechanisms is essential. This involves stringent authentication and authorization processes to ensure that only authorized personnel can access and modify the system.

Additionally, employing encryption techniques for data transmission and storage can safeguard sensitive information from unauthorized access. Creating a strong firewall and keeping it updated with security patches is important for improving SCADA system security. Regular security audits and vulnerability assessments can also identify any potential weaknesses and prompt necessary actions to mitigate risks.

IoT Integration with SCADA Systems for Seamless Connectivity

The integration of Internet of Things (IoT) technology in Next-Gen SCADA Systems has revolutionized the industrial landscape. As SCADA systems continue to evolve, IoT offers the potential for seamless connectivity between devices and applications, enhancing data acquisition and control. This integration allows for real-time monitoring and data exchange, resulting in more efficient and responsive operations.

One key aspect of IoT integration in SCADA systems is the ability to leverage data analytics. SCADA systems analyze data from connected devices to provide valuable insights because of the large data volume.

Operators can use advanced analytics to understand processes and make data-driven decisions using machine learning and AI. This data analysis not only enhances operational efficiency but also enables predictive maintenance and proactive troubleshooting to prevent potential issues.

Case Studies: Successful Implementations

Successful implementations of next-gen SCADA systems have been observed in various industries, showcasing the advancements and benefits they bring to industrial automation. One notable key aspect that has contributed to their success is the integration of cloud technology. By harnessing the power of cloud computing, these SCADA systems have experienced improved scalability and flexibility.

Cloud integration in industrial automation allows for efficient data storage, analysis, and processing, resulting in better decision-making capabilities for businesses. Real-time data can be securely transmitted and accessed from anywhere, enabling remote monitoring and control. Furthermore, cloud integration enables seamless collaboration between different stakeholders, enhancing overall operational efficiency in industrial processes.

Another critical element that has been pivotal in the success of next-gen SCADA systems is the implementation of edge computing. This innovative approach involves transferring data processing and analysis closer to the source, reducing latency and ensuring real-time insights.

Edge computing empowers SCADA systems to handle large volumes of data efficiently, allowing for optimized control and monitoring. Additionally, edge computing improves the response time of SCADA systems, enabling rapid action and reducing downtime in industrial processes.

Furthermore, leveraging edge computing for real-time processing enhances the overall reliability and performance of SCADA systems, making them more resilient in challenging operational environments.

Addressing cybersecurity challenges is of paramount importance for successful SCADA system implementations. As SCADA systems become more interconnected and integrate with various other technologies, the risk of cyber-vulnerabilities increases. To ensure the security and integrity of next-gen SCADA systems, robust cybersecurity measures must be implemented.

This involves adopting multi-layered security protocols, including firewalls, intrusion detection systems, encryption, and access control mechanisms. Additionally, regular security audits and updates are crucial to identify and address potential vulnerabilities. By prioritizing SCADA cybersecurity, organizations can mitigate the risks associated with cyber threats, ensuring the smooth and secure operation of their industrial processes.

Challenges and Solutions in Next-Gen SCADA

SCADA (Supervisory Control and Data Acquisition) systems have revolutionized industrial operations by providing real-time monitoring and control capabilities. However, the integration of IoT technology into SCADA networks has presented both challenges and solutions.

One of the key challenges is the synergy between IoT and SCADA. IoT sensors collect and analyze data. However, integrating them into SCADA networks requires careful consideration. This is necessary to address compatibility and security concerns.

Ensuring that IoT devices can seamlessly communicate with SCADA systems while maintaining the integrity and confidentiality of data is crucial.

Moreover, the advent of IoT sensors in SCADA networks has also raised concerns regarding network scalability. With an increasing number of IoT devices being deployed, scalability becomes a significant challenge for SCADA systems. Designing a network infrastructure that can accommodate the growing IoT ecosystem while maintaining optimal performance is essential.

Additionally, the utilization of AI in predictive maintenance is another solution to address the challenges in next-gen SCADA systems. By using AI algorithms to analyze data collected from IoT sensors, predictive maintenance can be carried out, enabling proactive decision-making and reducing downtime.

AI algorithms can identify potential equipment failures or performance issues, allowing operators to take preventive measures before costly breakdowns occur.

In conclusion, careful planning and implementation can overcome the challenges associated with IoT integration and network scalability in next-gen SCADA systems. Combining IoT and SCADA, along with using AI for predictive maintenance, are important for solving these problems.

As the industrial landscape continues to evolve, it is imperative that SCADA engineers remain proactive in finding innovative solutions that ensure the efficiency, security, and reliability of next-gen SCADA systems.

Role of AI in Next-Gen SCADA Systems

Machine learning and artificial intelligence (AI) have emerged as crucial components in the advancement of next-generation SCADA systems. By leveraging AI algorithms and techniques, these systems are able to adapt and optimize their operations dynamically, resulting in enhanced efficiency and performance.

One key area where AI has proven particularly beneficial is machine learning in SCADA. SCADA systems use smart algorithms to analyze lots of data quickly. They can find patterns, make predictions, and spot any unusual things that might mean there are problems or risks.

SCADA case studies have demonstrated the effectiveness of incorporating AI into next-gen systems. AI algorithms analyze past water data to find patterns indicating a potential pipe burst or abnormal usage. This early detection enables proactive maintenance, reducing downtime and minimizing potential damage.

Additionally, integration challenges have long been a concern in SCADA systems, particularly when implementing AI technologies. However, advances in technology and connectivity options have significantly facilitated the integration of AI algorithms into existing SCADA systems, allowing for seamless compatibility and cooperation between the two domains.

Overall, the role of AI in next-gen SCADA systems is crucial for enabling intelligent decision-making and automation. By leveraging machine learning algorithms and analyzing extensive amounts of data, these systems can identify patterns, predict future outcomes, and improve overall operational efficiency. While challenges in integration persist, ongoing technological advancements continue to pave the way for seamless AI integration into SCADA systems, offering tremendous potential for further advancement in the field.

Training and Skill Development for Engineers

Scalability and flexibility in industrial automation have become crucial factors in the modern world of SCADA systems. As technology continues to advance rapidly, it is imperative for engineers to stay updated with the latest trends and developments in the field.

SCADA engineer training plays a vital role in ensuring that professionals have the necessary skills and knowledge to design, implement, and maintain efficient and secure SCADA systems.

Future SCADA systems will focus more on integrating new technologies like AI and machine learning. Engineers must have the skills to use and benefit from these technologies in SCADA systems.

Training programs should improve engineers’ ability to adapt to new technologies, keeping them innovative in the industry. Organizations can train and develop a skilled team of engineers. This team will be able to easily handle advanced SCADA systems. Offering training and skill development opportunities is the key to achieving this.