A Comprehensive Guide to Control Panel Project Management

Control panel project management involves efficiently coordinating and executing tasks. These tasks relate to the design, engineering, assembly, testing, and documentation of control panels. These panels are important in automation systems, serving as the main hub for monitoring and controlling equipment and processes.

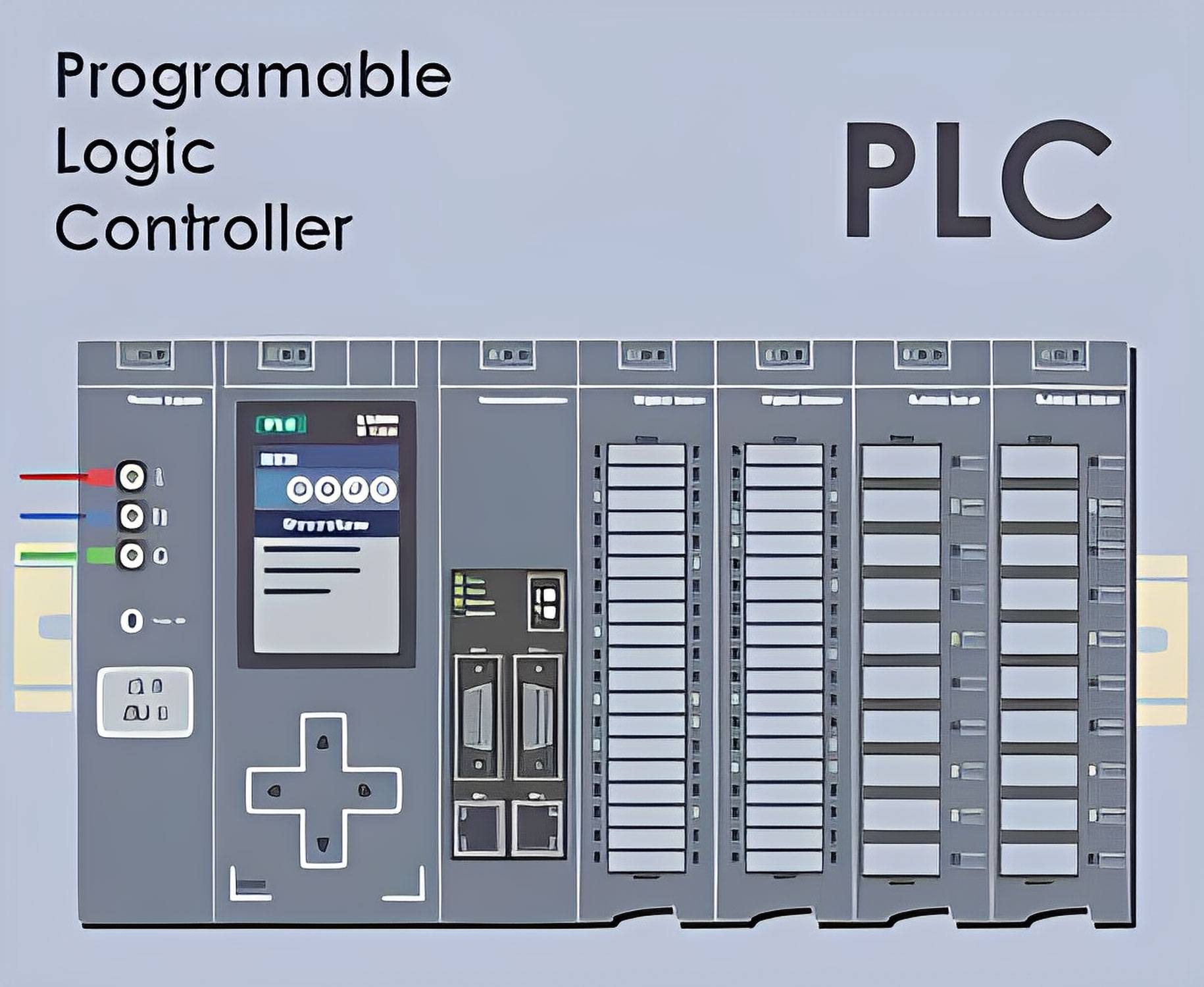

Proper project management is essential for successful outcomes. This is particularly true when using an MCC panel or a PLC control panel to control motors.

Effective control panel project management begins with thorough planning. This phase includes outlining project objectives. It also involves defining the scope and deliverables.

Lastly, it includes creating a detailed timeline. The design and engineering phase turns requirements into technical specs and creates a layout for the control panel.

After that, we obtain and handle the necessary parts to meet the project requirements. Assembly and integration involve building the control panel, connecting components, and integrating with the automation system. Afterwards, we perform rigorous testing and validation to ensure proper functionality and adherence to industry standards.

Importance of Effective Project Management in Automation

Good project management is important in the automation industry. This is especially true for making and using automation control panels. Automation control panels are highly complex systems. They require meticulous planning, precise execution, and continuous monitoring.

Without efficient project management, the chances of encountering delays, budget overruns, and subpar quality in the completion of control panel projects increase significantly.

Effective project management is crucial in automation control panel projects. It ensures smooth coordination among stakeholders. A well-managed project makes sure that various teams, like design, engineering, procurement, assembly, and testing, collaborate well.

The project manager is the main person in charge. They help with communication, solve problems, and make sure everything is working towards delivering the automation control panel successfully. By managing the project well, the manager can reduce risks, avoid problems, and maintain good quality throughout the project.

Control Panel Project Planning Phase

The Control Panel Project Planning Phase is an essential stage in the overall project management process. In this phase, we carefully consider important factors for successful project execution. The design and engineering of the PLC control panel are important factors to consider.

The design and engineering of the PLC control panel are critical aspects of the project planning phase. It involves creating a comprehensive blueprint that outlines the specifications, functionalities, and components of the control panel. This involves deciding the right panel size, layout, and placement and selecting the appropriate PLC hardware and software.

The design and engineering process includes researching and analyzing to make sure the control panel meets requirements and standards. Project managers can align design and engineering with their goals, ensuring smooth integration and successful control panel implementation.

The design and engineering of the Control Panel Project

Design and engineering are important for making a control panel project efficient and effective. One of the key components of this phase is the design of the VFD control panel, which stands for Variable Frequency Drive. The VFD control panel controls motor speed and torque, giving more control and saving energy.

In addition to the VFD control panel, the design process involves selecting and integrating other components. These components include circuit breakers, relays, meters, and switches. We chose these components based on the specific requirements and specifications of the control panel project.

The engineering team figures out the right wire sizes, cable lengths, and voltage drop to ensure good performance. Thorough design and engineering guarantee that we set up the control panel project for success from the very beginning.

Procurement and Material Management for the Control Panel

Procurement and material management are crucial aspects of control panel project management. The smooth execution of a project heavily relies on the timely availability of the required components and materials. When it comes to control panel projects, one of the key components is the HMI, or Human Machine Interface.

The HMI is a control panel part that allows operators to interact with and control monitored equipment or systems. During procurement, we choose the right HMI for the control panel project, ensuring it works well with the project’s needs.

Effective material management plays a significant role in ensuring the seamless operation of control panel projects. Various components, such as power supplies, circuit breakers, relays, and wiring, compose control panels. We must obtain, monitor, and handle these materials well to prevent any delays or interruptions in the project schedule.

Project managers can ensure they have the materials they need by maintaining an organized inventory and tracking system. This helps to reduce delays and improve project efficiency. Proper material management helps with budgeting and cost control, making sure procurement activities match the project’s financial goals.

Assembly and Integration

Assembly and integration of control panels are critical stages in the process of industrial automation. Once we complete the design and engineering phases, we gather the necessary components and materials for the assembly process. Skilled technicians and engineers work together to meticulously assemble each component, ensuring that all connections are secure and accurate. This stage requires attention to detail and precision to ensure the control panel operates effectively.

Integration involves connecting the control panel to the automation system, such as the industrial automation SCADA system. This step allows easy communication and control between the control panel and other devices or systems in the automation project.

We test and validate the control panel to ensure it works correctly and meets the requirements. This phase is crucial to guaranteeing the safe and efficient operation of the control panel in industrial automation applications.

Testing and validation processes

During the testing and validation phase of a control panel project, it is crucial to ensure that the industrial control panel wiring is functioning correctly and in compliance with the applicable standards and specifications. This phase tests the control panel’s parts and functions to make sure they work correctly.

Testing typically includes various electrical, mechanical, and functional tests to assess the performance and reliability of the control panel. These tests may involve checking the voltage and current levels, verifying the proper sequencing of operations, and confirming that all safety features are in place and functioning correctly.

The validation process ensures that the control panel meets the required industry standards and regulatory requirements, providing assurance that it is safe to use and complies with all necessary guidelines.

Thorough testing and validation can identify and resolve any potential issues or deficiencies with the industrial control panel wiring, ensuring the overall quality and effectiveness of the control panel system.

Project Documentation

Project documentation plays a crucial role in ensuring the smooth execution of control panel fabrication projects. From the initial planning phase to the final implementation, documentation serves as a detailed record of all project activities. This detailed documentation helps track project progress and enables effective communication among all involved stakeholders.

By documenting the project requirements, specifications, and any changes or modifications made along the way, project documentation ensures that the control panel fabrication project stays on track, minimizing the risk of errors or miscommunication.

Furthermore, project documentation serves as a valuable reference for future projects. It provides an organized overview of the control panel fabrication process and acts as a repository of knowledge for the project team. We document any lessons learned, best practices, or recommendations to improve future projects.

Additionally, project documentation also plays a crucial role in compliance, as it provides evidence of adherence to quality standards, regulations, and industry guidelines. With well-documented project documentation, control panel fabrication projects can achieve greater efficiency, minimize risks, and maintain a continuous improvement process.

Project Monitoring and Control

During the project monitoring and control phase, it is crucial to closely track the progress and performance of the control panel project. This involves regularly monitoring the project activities, analyzing their results, and adjusting the project plan as needed. We closely monitor key metrics such as project schedule adherence, cost variance, and resource utilization to ensure the project stays on track and meets its objectives.

One important aspect of project monitoring and control is risk management. This includes finding risks that could affect the project, evaluating their impact, and creating plans to reduce their impact.

By actively monitoring and managing risks throughout the project, the control panel’s project team can proactively address challenges and prevent any potential issues from derailing the project’s success.

Project monitoring and control requires good communication and teamwork to make sure everyone is working together towards the project’s goals. Regular meetings and updates keep everyone informed and enable timely decision-making for project issues or changes.