Introduction of Industrial automation and need of Custom Design Control Panel Fabrication

Industrial automation has become an integral part of the modern manufacturing and production sector. Its seamless combination with custom designed control panel fabrication underscores its overall efficiency. A correctly fabricated main distribution panel forms the backbone of any industrial process automation.

It securely facilitates the distribution of electrical energy across the facility. Consequently, it curbs unnecessary downtime caused by electric failures, crucial for maintaining the production rhythm of an industrial unit.

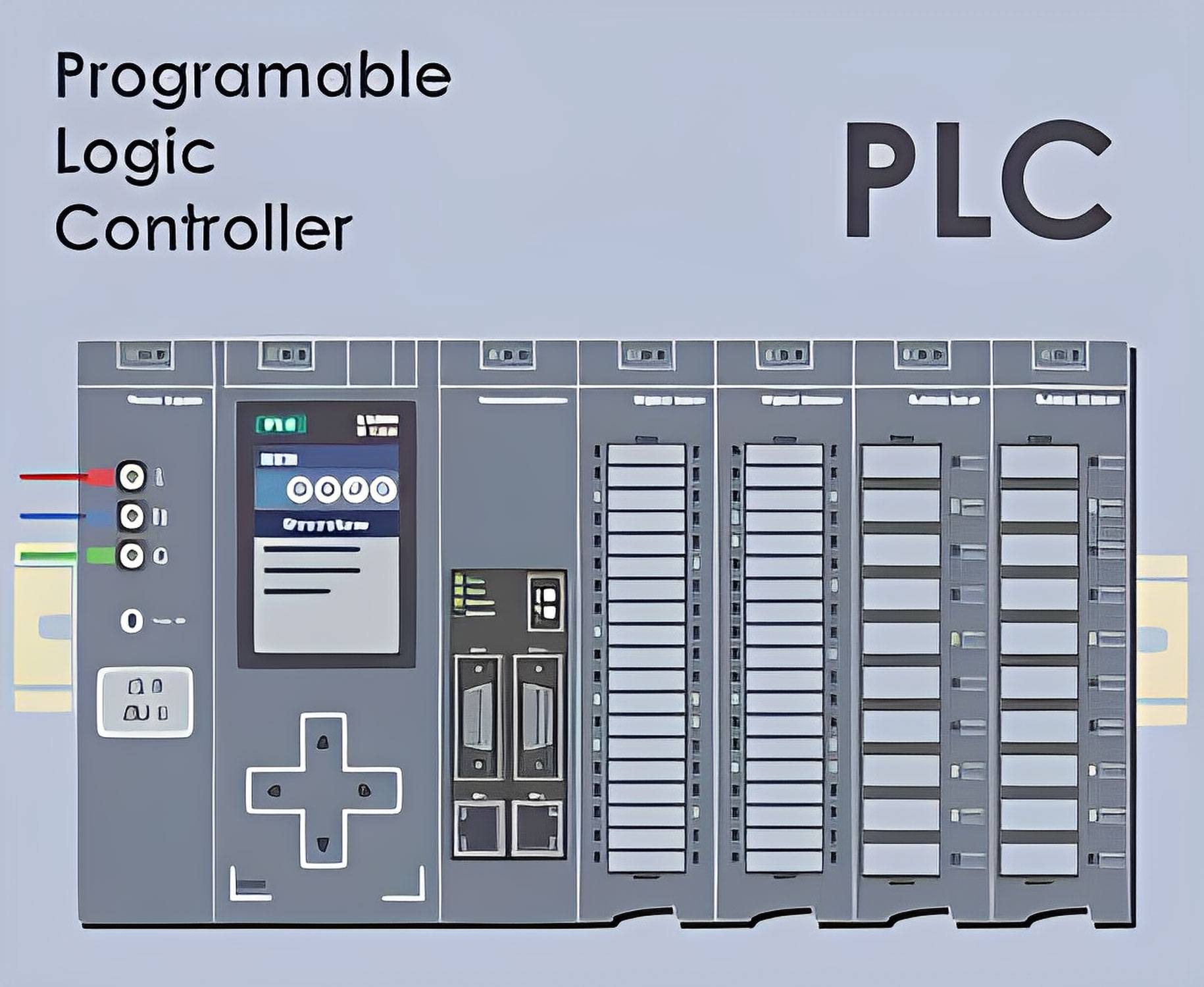

HMI integration and Schneider PLC Control panel are important to plant engineers and industry professionals in this situation. HMI aids in visually representing the process control data, allowing operators to control and monitor operations in real-time. Schneider PLC panels are reliable for controlling automation and used for industrial power distribution.

Integrating such state-of-the-art technologies into a custom control panel fabrication is no easy task. To solve a problem, you need to understand the situation, the difficulties, and the best solution. Custom-made control panels are perfect for this situation.

Significance of Tailored Solutions Control Panel in Industrial Automation

Tailored control solutions are at the heart of every modern industrial Automation Control Panels. By providing carefully designed systems that precisely meet individual factory requirements, these solutions maximize efficiency, reduce project completion time, and increase overall results.

Top automation design services provide custom solutions to meet specific needs. They utilize their expertise and technology to create efficient systems. These systems improve the automation process and enhance product output.

Bespoke control panel manufacturing plays a significant role in this sphere. Using a special control panel for industry improves production, accuracy, and reduces system failures.

Adding advanced HMI services to control panels improves operator-machine interactions and monitoring, reducing operational errors. Turnkey control system solutions provide a complete package with custom manufacturing, advanced HMI integration, thorough testing, and delivery. They help industries transition smoothly and efficiently to automation.

Exploring the Role of Advanced Control Systems

Advanced control systems have greatly transformed customized industrial power distribution, which is crucial for generating, dispersing, and controlling electricity. At the heart of these systems lies specialized PLC panel design.

Control panel engineering companies combine modern and traditional methods. This combination creates a strong structure. The strong structure improves plant operations and infrastructure. Additionally, it protects against power failures.

These augmentations, in turn, bolster overall productivity, minimize costs, and enhance user experience – laying the foundation for greater industrial automation.

In conjunction with customized power distribution, the role of innovative control logic design in process automation is fundamental. This involves creating algorithms and strategies to automate industrial operations. It also includes developing user-friendly interfaces that display process data and allow operators to interact. Additionally, it involves controlling automated processes in real-time.

Overall, advanced control systems are transform various industries by boosting efficiency levels, streamlining operations, and promoting greater user engagement.

Material Selection and Component Integration

Using new materials in control panel production has made affordable panel making and checking panel parts popular. This means that we can meet even complex industrial automation needs without excessive spending.

Modern control panels use customizable materials like polymers and metals to be efficient, durable, and affordable. They also have components that can resist high temperatures.

Choosing the right materials for control panels is important for the printer’s performance and durability.

To handle growing complexities, it is crucial to collaborate with skilled control system designers. These designers have the ability to accurately select and combine the appropriate hardware. They also excel at utilizing different components effectively.

This includes considering factors such as conductivity, resistance, stiffness, strength, and temperature tolerance. They choose different parts based on their electrical conductivity, resistance, rigidity, strength, and heat resistance.

Combining these quality-control panel parts can greatly improve the efficiency of automated systems. Consequently, these integrated hardware solutions address a broad spectrum of industrial challenges, paving the way for innovative automation solutions.

• Modern materials used in control panel construction:

◦ Sturdy polymers: These are highly durable and versatile, capable of withstanding high levels of stress without compromising on performance. They also have excellent electrical properties, making them ideal for use in control panels.

Composite metals combine strength and lightness, making strong and lightweight control panels possible. Their superior conductivity makes them perfect for electrical applications.

◦ Superior thermal resistant components: These can withstand extreme temperatures without losing their functionality. This makes them particularly useful in industries where high-temperature operations are common.

• Selecting compatible hardware:

Expert system designers are important. They know how to choose the right hardware. Factors like conductivity, resistance, stiffness, strength, and temperature form the basis for this.

• Seamless integration of components:

The integration process is equally important as it ensures all selected hardware works together optimally. Properly integrated systems result in increased efficiency and longevity of the automated systems.

Experts can create cheaper solutions with new materials and engineering techniques. These solutions have the potential to revolutionize industrial automation and solve challenges faced by different industries.

Cost-Effective Strategies

In making custom control panels, it’s important to find a balance between performance and budget. Control panel testing services are important for maintaining high standards of functionality and efficiency in the process.

This process ensures that the final product is both efficient and affordable. Companies can trust these testing services to provide high-quality solutions that meet their specific needs.

The adoption of prototyping for custom control panels fosters an environment where ingenuity thrives. It feeds into the core ethos of value engineering in automation. This approach allows for the swift identification of potential design and functionality flaws early in the production process.

Control panel fabrication case studies demonstrate practical control solutions that enhance efficiency and maintain the original design quality. These case studies strengthen the approach by providing real-life examples. The solutions showcased in these studies improve efficiency without compromising the original design quality.

Prototyping and value engineering are crucial for industrial automation, as they help achieve maximum efficiency and superior quality.

Testing and Validation Protocols

Industry 4.0 automation has made testing and validation of custom control panels stricter and more integrated. Commercial control panel manufacturers today emphasize the iterative prototyping process, where each prototype undergoes exhaustive testing aimed at incremental improvement with each iteration.

We test the control panels and use predictive modeling to plan for future trends in panel design. This process aids in future-proofing the products, while also ensuring they meet stringent quality and efficiency standards.

Materials used in control systems are advancing at a rapid pace, need reassessments of traditional testing protocols. We must test new materials for control systems in various conditions to make sure they are strong and can handle heat.

Additionally, as Industry 4.0 automation technologies incorporate more sophisticated features, there is an urgent need to develop optimized power distribution solutions. Proper power management can prevent overloads and shorts, resulting in safer, more efficient panels. Therefore, rigorous testing and continuous prototyping are non-negotiable for manufacturers committed to delivering customizable and reliable control panel solutions.

Real-World Implementations

The innovative incorporation of machine learning in control design is revolutionizing industrial automation. As evidenced by the trailblazing roll-out in a leading automobile manufacturing plant, the results have been profound. The control panel used AI to quickly and accurately adjust to unexpected changes on the assembly line. The system effectively improved production efficiency by 20% and reduced equipment downtime.

A company’s user-focused approach to panel fabrication was different from traditional methods and had a big impact. Control panel compliance expertise ensured adherence to safety and industry standards, while maintaining a user-friendly interface.

This, in turn, greatly reduced the time required for system make conversant and transition for operations staff. We also achieved control system cost optimization, resulting in a significant reduction in extra expenses. Such real-world implementations exemplify the transformative potential of custom-designed control panels in specific industrial applications.