Introducing Industrial Automation Integration Solutions, where technology meets industrial automation. Our expertise enables excellent operations and boosts efficiency. From control panel installation to crafting custom PLC, HMI, and SCADA solutions, we blend modern production machinery. As experts, we bridge the gap between automated systems, optimizing communication for optimal performance.

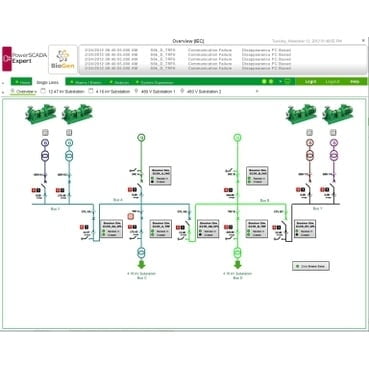

Automation Control Panels play a important role in automating production processes. Integration further simplifies these systems by connecting elements like software infrastructure and network security. An prominent example is supervisory control and data acquisition (SCADA), which integrates software and hardware to facilitate remote or local control and monitoring of industrial processes, complete with real-time data processing.

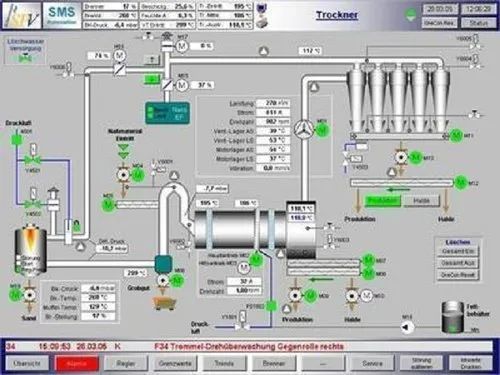

System integration primarily revolves around electrical control panels. These panels encompass customizable elements such as programmable logic controllers (PLCs), variable frequency drives (VFDs), and silicon-controlled rectifier (SCR) power thermal systems. This synergy ensures a comprehensive orchestration of industrial operations for optimal efficiency and control.

TYPES OF AUTOMATION SYSTEMS INTEGRATION

SCADA Integration: By intertwining software systems with Web HMIs, user interfaces become conduits for interacting with real-time server data. This accessibility extends to devices connected to the internet. Harmonizing HMI and SCADA systems yields enhanced capabilities.

Automation Components: Each control panel embraces customizable components capable of automating machine-level tasks. From regulating motor speed to initiating start/stop operations, these components exhibit intelligence-driven functionality.

PLC Integration: Proficient system integrators engineer, program, and configure PLCs and RTU-based control systems. These powerhouses find applications in realms like wastewater collection and oil field operations. By synergizing sensors and data analysis, key performance indicators contribute to heightened productivity and profits.

VFD Advancements: Robust Variable Frequency Drives (VFDs) excel in various environments, from deserts to mountains. Their merits encompass adapting to changing irrigation needs, curbing maintenance costs, and boosting crop quality. In wastewater treatment facilities, VFDs assume control over water pump systems, regulating pump speed for optimal operation. Leveraging variable speed drives can significantly offset project expenses.