SCADA systems, or Supervisory Control and Data Acquisition systems, play a pivotal role in modern industrial operations. These advanced technologies enable the monitoring, control, and management of complex processes across various industries. Explore Custom SCADA Solutions with our advanced SCADA systems, Tailored to your needs, systems enhance efficiency and control

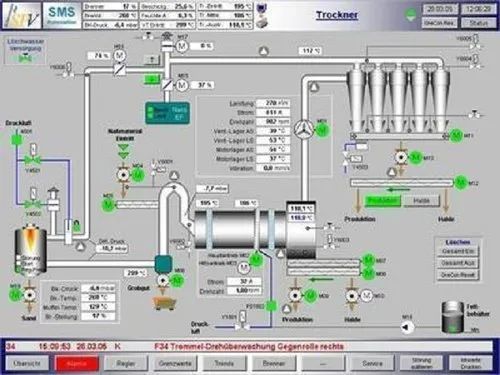

SCADA systems collect real-time data from sensors and devices, presenting it through user-friendly interfaces. This empowers operators to make informed decisions promptly. Moreover, systems facilitate remote control, allowing operators to optimize processes in real-time, enhancing efficiency and minimizing downtime.

From manufacturing and energy production to transportation, SCADA are versatile tools that bridge the gap between humans and machinery. They offer a comprehensive view of operations and enable swift intervention when needed.

What is SCADA system?

SCADA , short for Supervisory Control and Data Acquisition systems, are a vital component of modern industrial organizations. We design systems to efficiently monitor and control various processes and equipment. A regular SCADA consists of hardware, software, and networks. These components work together to collect data from remote locations. The system then provides operators with real-time information.

A SCADA is a centralized control system, allowing operators to monitor and control industrial processes remotely. It gathers and studies information from sensors and devices like valves, pumps, and motors to guarantee efficient operations. The user interface shows the data, giving operators a complete view of how the system is performing. SCADA software allows operators to set alarms and alerts for fast response to unusual events or process changes.

How does a SCADA system work?

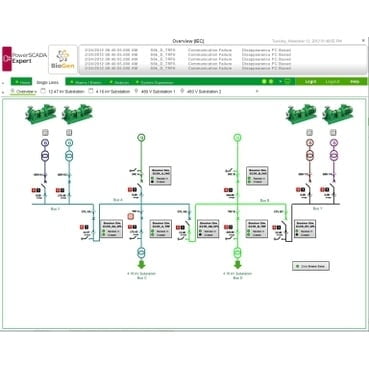

A SCADA system monitors and controls processes and equipment in real-time using a complex control system. It operates with three main components: supervisory computers, remote terminal units (RTUs) or programmable logic controllers (PLCs), and communication infrastructure.

Furthermore, SCADA are crucial in enhancing operational efficiency by automating manual tasks, reducing downtime, and optimizing resource utilization. They also enable centralized decision-making, as operators can quickly identify and address issues from a single location. With the ability to collect vast amounts of data, SCADA software facilitate data-driven decision-making, helping organizations improve productivity, quality, and safety.

Industrial organizations design SCADA to efficiently monitor and control various processes and equipment.

Why are SCADA systems crucial in an industrial organization?

SCADA systems play a crucial role in industrial organizations because of their ability to control and monitor various processes. These systems combine various parts, like the SCADA network, PLC SCADA, and HMI SCADA, to manage industrial operations effectively.

These systems are important because they can automate processes, making them more efficient and productive. By connecting and controlling multiple devices and sensors, streamline operations, reducing the need for manual intervention.

This allows industrial organizations to optimize their resources and minimize human error, ultimately leading to cost savings and enhanced overall performance. Additionally, SCADA provide real-time data monitoring, allowing operators to make informed decisions promptly.

Having accurate data quickly helps organizations respond to critical situations, run smoothly, and prevent disasters.

Who uses SCADA?

Various industrial sectors extensively use SCADA to monitor and control critical operations. Experts in SCADA programming, who have a strong grasp of analyzing SCADA data, mainly use these systems.

They play a pivotal role in ensuring smooth operations, reducing human intervention, and enhancing efficiency. Knowledgeable engineers, technicians, and operators in industries use SCADA for automation. These experts use SCADA to gather live information from various distant devices, like sensors and industrial machinery.

By studying this data, they can make smart choices, find problems, and quickly fix any possible faults or malfunctions. SCADA can easily connect with other control systems, letting operators oversee and manage multiple processes at once, improving overall productivity.

Key Components of Contemporary SCADA Systems

In contemporary SCADA systems, one of the key components is the automation control panels. These panels play a crucial role in monitoring and controlling the various processes within an industrial organization. Equipped with advanced technologies, these panels enable operators to command and supervise the operations of different devices and machines with efficiency and precision.

They provide real-time data acquisition and allow for quick responses to any changes or anomalies in the system. Additionally, designers create automation control panels to be user-friendly, enabling operators to navigate and manipulate the system effectively.

Another essential component of modern SCADA is the PLC control panel. PLC, an acronym for Programmable Logic Controller, controls various industrial processes using a digital computer. The PLC Control Panel is like the brain of the system. It gets input from sensors and peripherals and controls things based on that.

Data processing, decision-making, and executing commands are important to ensure smooth and efficient industrial processes. Programmable logic allows the customization of control panels to meet organizations’ specific requirements, improving their effectiveness and reliability in industrial automation.

Cybersecurity in SCADA Systems

As industrial organizations increasingly rely on SCADA systems for their operations, ensuring cybersecurity becomes imperative. Protecting systems from unauthorized access and cyberattacks is very important due to interconnected networks and increasing threats.

One critical aspect of cybersecurity in SCADA is authentication. Strong authentication mechanisms, such as multi-factor authentication, are crucial in preventing unauthorized individuals from gaining access to the system.

This ensures that only authenticated personnel with the proper credentials can control and manage the industrial processes. Implementing strict user access controls and regularly updating and reviewing user privileges are also essential security measures to prevent unauthorized access and potential vulnerabilities. Additionally, regularly changing and updating passwords, as well as enforcing password complexity requirements, further enhances the security of SCADA.

Another vital element of cybersecurity in SCADA systems is data encryption. SCADA handle vast amounts of sensitive data, both in transit and at rest. Encrypting data adds extra security, making it difficult for hackers to understand or change the information.

By using strong encryption, organizations can protect their important data from unauthorized access and maintain system privacy and integrity. Regular security audits and vulnerability assessments help find and fix security gaps, making SCADA systems more secure.