Control Panel Fabrication is the design and construction of custom control panels. Efficient automation and control systems involve integrating components like PLC Control panel and HMI Control Panel.

Custom Control Panel Fabrication is a complex task, it requires accuracy and knowledge. This fabrication primarily manages and control panel installation, functions that influence industrial machine performance.

One of the primary goals of this procedure is to improve the overall efficiency of industrial processes.

Moreover, industrial automation plays a crucial role in enhancing workplace safety. By replacing manual labour with automated systems, companies can minimize the exposure of workers to hazardous environments and potentially dangerous tasks.

Industrial Pump Control Panel:

Designing robust control panels optimizing pump efficiency, ensuring seamless industrial operations and minimal downtime through smart automation.

Industrial AOD Pump Control Panel:

Implementing cutting-edge AOD pump control solutions, enhancing industrial fluid handling with precision, reliability, and advanced automation capabilities.

pH and Flow Monitoring Panel:

Developing intelligent control panels integrating pH and flow monitoring, ensuring real-time analytics for precise industrial processes and quality control.

Leak Alarm Control Panel:

Crafting responsive control panels equipped with leak alarm systems, swiftly detecting and addressing potential issues to safeguard industrial environments and assets.

Hazardous Area Panel:

Engineering specialized control panels for hazardous areas, prioritizing safety with intrinsically safe components and advanced monitoring for risk mitigation.

Custom Control Panel Fabrication:

Tailoring bespoke control panels, from conceptualization to fabrication, meeting unique industrial needs with precision, innovation, and unmatched expertise in customization.

Industrial automation plays a crucial role in enhancing workplace safety. By replacing manual labour with automated systems, companies can minimize the exposure of workers to hazardous environments and potentially dangerous tasks.

Additionally, this procedure enables companies to achieve higher levels of precision and accuracy in their operations. Automated systems can consistently perform tasks with minimal errors, ensuring that products meet the required quality standards. This level of precision is particularly important in industries such as pharmaceuticals, electronics, and automotive manufacturing, where even minor errors can have significant consequences.

Furthermore, industrial automation allows for better resource management. By optimizing the use of energy, materials, and other resources, companies can reduce waste and minimize their environmental impact. This procedure enables businesses to adopt sustainable practices and contribute to a greener and more eco-friendly future.

Each step of control panel fabrication requires careful thought and planning. The process includes assembling power circuits, control circuits, and terminal sections. You must do this carefully, considering both design and safety aspects.

Creating automation control panels are crucial for efficient industry automation. Electrical control panel fabrication may be complex, but it’s important.

Our Expertise:

At Unicorn Global Automations, we have a lot of experience. We make control panels, PLCs, and VFDs for industrial automation, driving progress in this field.

Key services offered:

- Control Panel Design and Engineering:

- Tailored designs for your specific needs.

- Prioritizing functionality, efficiency, and compliance.

PLC Programming:

- Smooth automation requires expert programming.

- Customized solutions for diverse industrial processes.:

VFD Integration

- Seamless integration of variable frequency drives.

- Optimal motor speed control for enhanced efficiency.

- Importance of Well-Designed Control Panels in Industrial Automation

Automation control panels are the heart of industrial processes. You must pay attention to the design and functionality of vital electronics.

They house important components like PLCs and VFDs. Well-designed control panels originate and optimize efficiency. It also reduces the risks of mechanical failures and operator errors significantly.

A good control panel improves reliability, safety, and production efficiency in industrial settings. It integrates and sequences a VFD control panel effectively for machinery operation.

Troubleshooting is easier with these panels. They predict problems in advance and save time and resources. Well-designed automation control panels are crucial in industrial automation.

Our Experience in Control Panel Fabrication

We have gained a lot of knowledge and experience in integrating PLC control panels for industrial automation. Our team has experience in different industries and applications. This has given us knowledge about the specific requirements for control panel projects.

We have improved our processes and efficiency by working on many control panel projects. We can now create high-quality custom control panels quickly.

At Unicorn Global Automations, we can create a control panel that meets your basic or complex needs. We have the skills and experience for any project.

We are a trusted name in automation control panel fabrication and switchgear panel installation. This is because of our experience, quality, customer service, and customized solutions. We have extensive experience in this field.

We are committed to providing high-quality products. Our customer service is exceptional. We offer customized solutions to meet our customers’ needs.

We are dedicated to quality, and we prioritize customer service. We provide tailor-made solutions. Our dedication has established us as a trusted name in control panel fabrication.

Expertise in automating control panels, PLCs, and VFDs.

To meet the needs of modern industries, you must be skilled in controlling automation panels, PLCs, and VFDs. This knowledge comes from understanding how these parts work together with other elements in an automation system.

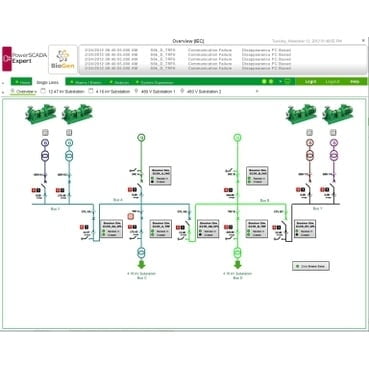

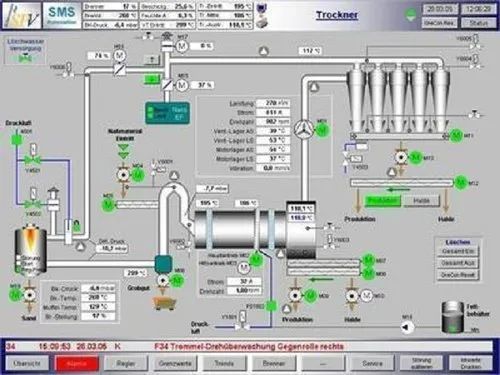

Most significant are the SCADA systems, an acronym for Supervisory Control and Data Acquisition. These systems monitor and control automated processes and machines. They play a crucial role in various industrial applications. These applications include managing energy, treating water, and automating factories.

Another important aspect of this specific field is installing electrical panels. Proper installation is crucial for the efficiency and safety of an industrial setup. This involves planning the layout, routing wires, mounting components, and ensuring compliance with electrical codes and standards.

Every step is crucial for a successful result. Firstly, it is vital to plan the panel layout carefully. This includes arranging components optimally and considering accessibility and safety. Then, we efficiently organize wires to ensure proper connection.

This involves determining the most efficient pathways and organizing the wires neatly to avoid confusion. Then, we mount components correctly to ensure stability and functionality. This involves securely attaching them to the panel and following the manufacturer’s guidelines.

It is important to follow electrical codes and standards to ensure safety and reduce the risk of electrical dangers. Having strong skills in automation control panels, PLCs, and VFDs is crucial for completing these tasks accurately.

Main Distribution Panels (MDPs) are the cornerstone of any control panel fabrication, serving as the central hub for electrical power distribution in industrial settings. Crafted from high-quality woods that ensure durability and resilience, these panels play a crucial role in regulating electricity flow across various systems. Integrating state-of-the-art technologies like Schneider SCADA (Supervisory Control and Data Acquisition) and HMI control panel (Human-Machine Interface) elevates their functionality to new heights.

Why Choose Us:

- Experienced and skilled team

- Commitment to Innovation and Excellence

- Proven Track Record in Control Panel Fabrication

Industrial Automation Solutions

Industrial automation solutions improve manufacturing efficiency. They are essential in today’s industrial landscape. These solutions use advanced control panel systems with technologies like PLCs, VFDs, and HMI devices.

These systems serve as the hub of any industrial automation process. They enable smooth communication among various automated systems and greatly enhance productivity.

Control panel testing is a key step in verifying the performance and reliability of these systems. Rigorous testing procedures help identify potential issues that could hinder the operation of the automation process.

A key part of this is industrial control panel wiring, which forms the backbone of the control panel system. It connects panel parts to make them work well together and do their job effectively. Errors in wiring can cause problems or even system breakdowns, so it’s important to follow precise wiring protocols.

Key services offered

In the centre of our portfolio, Custom SCADA Solutions features prominently, serving as a testament to the adaptability and capabilities of our services. We use our experience and advanced technology to create automated systems.

These systems help clients monitor and control their industrial processes. They do so in a better and faster way. Our tailored solutions boost productivity, cut costs, and greatly enhance quality by meeting specific needs.

Specializing further, we also provide comprehensive services for power distribution panel setup. We provide reliable power distribution systems for industries to ensure smooth operations. We carefully plan, design, and install efficient electric panels to distribute electricity in your building safely.

We design our setups for tough industrial conditions, minimizing downtime and problems. We also offer tailored services for various industries.

- Industrial Automation Solutions: We deliver automation solutions. They are high-quality and streamline operations to increase efficiency. Our team is adept at integrating different systems into a unified, automated workflow.

- Process Control Systems: Our process control systems monitor and manage industrial processes effectively. These systems aid in maintaining consistent product quality while reducing waste and downtime.

- Energy Management Services: We offer energy management services. These services optimize energy consumption, reducing costs and environmental impacts. Our services include conducting energy audits, designing efficient power distribution networks, and implementing sustainable practices.

- We provide strong network security solutions to protect your data from threats. Our services include setting up secure networks and offering cyber-security consulting.

- Maintenance and Support Services: To ensure smooth operation after implementing our solutions, we provide ongoing maintenance and support services. This includes regular system checks, troubleshooting issues promptly when they arise, and software updates, among others.

- We are dedicated to providing excellent service and making sure customers are happy. We help businesses in a changing industry by using our knowledge and constantly generating new ideas.

Control Panel Design and Engineering

At the heart of industrial automation stands a meticulously designed control panel. Each stage of its engineering involves substantial knowledge and expertise, ensuring the optimal functionality of industrial machinery.

The process begins by analyzing and evaluating the system. This includes examining the equipment it will control and the environment it will operate in.

This first step is important for setting up the settings for a control panel. It forms the basis for configuring any control panel. The aim is to make a system that works well in challenging industrial settings, being flexible and efficient.

Integrating the right hardware and software components is pivotal in control panel engineering. We carefully select important elements like input/output designations, PLCs, and power ratings to meet industry regulations and standards.

Control panel design and engineering requires expertise across various areas and a commitment to continuous innovation.

Tailored designs for specific industrial needs

Each corporation in industrial automation has unique needs and requires customized control panel designs. Our skilled professionals understand each client’s industry environment, functional needs, and regulatory demands. They then draft a blueprint for the control panel.

We have a flexible engineering design process. This allows us to create control panels that fit well with an industry’s unique landscape. Additionally, it helps improve efficiency.

We create custom designs by understanding client requirements, using automation technologies, and prioritizing safety and regulatory standards.

We use CAD software. It generates precise and detailed designs. We consider factors such as spatial arrangement, worker safety, energy efficiency, and maintenance ease.

Our control panels meet industrial needs. They boost productivity and reduce downtime significantly. Every control panel must cater to the machinery it regulates. We crafted it to meet operational needs. Decisions about layout, automation, and component selection all depend on analysing the required functionality.

Furthermore, compliance is important. We design each system to adhere to regulations and standards. This commitment ensures panel longevity, safety, and performance in all applications.

PLC Programming

PLCs are the backbone of industrial automation processes. They control control panels and require expert programming. Programming affects efficiency, reliability, and safety. PLCs enable robust control strategies for complex tasks that demand precise programming to perform well.

We are specializes in control panel fabrication. We integrate custom PLC programming that meets industrial needs. Our coding solutions respond accurately and quickly to process parameters. They manage different equipment types and synchronization requirements.

Our team ensures our programming aligns with established standards, promoting interoperability and minimizing downtime. Maintenance becomes easier as a result. Ultimately, we empower control panels to optimize industrial automation with intelligence.