What dose Siemens SCADA do?

Siemens SCADA System actively controls and monitors industrial processes in real-time. It gathers data from sensors and devices, presenting it through a user-friendly interface. This software enables operators to remotely manage equipment and make informed decisions based on the collected data. Additionally, SCADA aids in optimizing operations, enhancing efficiency, and ensuring safety across industries like manufacturing, energy, and utilities.

Siemens SCADA actively controls and monitors industrial processes in real-time. It gathers data from sensors and devices, presenting it through a user-friendly interface. This software enables operators to remotely manage equipment and make informed decisions based on the collected data. Additionally, Siemens SCADA aids in optimizing operations, enhancing efficiency, and ensuring safety across industries like manufacturing, energy, and utilities.

Siemens SCADA (Supervisory Control and Data Acquisition) System is a comprehensive software platform designed for industrial automation and monitoring. It enables real-time data acquisition, visualization, and control of processes across various industries. With advanced features and robust capabilities, SCADA Siemens System enhances work efficiency and facilitates informed decision-making.

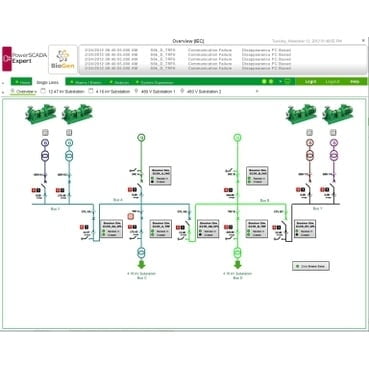

Experience a new level of process control and project insight with the advanced Siemens SCADA Software. Siemens offers a robust solution designed for seamless control and monitoring of industrial processes. At its core, it provides a sophisticated Human-Machine Interface (HMI) that enables real-time visualization and control.

SCADA Siemens system boasts a modular and scalable system architecture. Its centralized and distributed control capabilities empower industries to adapt to varying automation needs. The Human-Machine Interface (HMI) facilitates intuitive graphical representations, ensuring operators have a comprehensive view of the entire system.

Importance of SCADA in Industrial Automation

With the rapid advancements in technology, industrial automation has become an integral part of various industries. It plays a crucial role in enhancing productivity, improving working efficiency, and reducing manual efforts.

Industrial automation with SCADA brings several benefits to the table. First, it helps industries collect live data from different devices and sensors in the plant or facility. Siemens SCADA software features helps operators and engineers make smart choices using current and precise data.

Discover the definitive Siemens SCADA implementation guide, empowering industries with seamless integration and optimized control. Explore best practices for configuration, security, and performance enhancement.

Using the Siemens technology, industries can elevate product efficiency and unlock the full potential for unparalleled automation control and create useful project insight.

Siemens SCADA Features

SCADA software for manufacturing industries plays a crucial role in ensuring efficient process control with Siemens SCADA. This software provides a wide range of features that enable smooth operations and enhanced productivity in industrial automation.

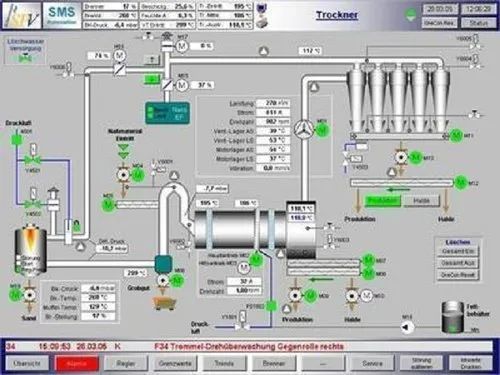

SCADA can collect data on temperature, pressure, and flow rates in real-time. This information helps manufacturers make better decisions, find problems, and enhance production processes. With Siemens system, manufacturers can easily address any issues because they have a full understanding of their operations.

You can analyse this data to make informed decisions, identify issues, and improve production processes. Siemens SCADA provides manufacturers with a complete view of their operations, helping them quickly respond to any problems.

Another key feature of Siemens SCADA is its advanced alarm and event management system. Siemens automation helps operators quickly detect important events such as equipment problems or process issues. This allows operators to react fast and efficiently.

Siemens SCADA System for manufacturing industries features includes custom alarms by priority to quickly address important issues in industrial automation operations. With these features, Siemens SCADA empowers manufacturers to maintain high levels of safety, reliability, and efficiency in their operations.

Data Acquisition and Control

SCADA systems play a fundamental role in the industrial automation landscape by enabling effective data acquisition and control. To achieve seamless communication and integration within the SCADA network, the utilization of robust SCADA communication protocols is crucial. These protocols facilitate the transmission of data between the various components of the SCADA system, ensuring reliable and efficient data acquisition.

When designing a SCADA system with Siemens, a comprehensive understanding of data acquisition and control is imperative. The system design should involve selecting and utilizing appropriate methods for gathering data from various sources. You can achieve this by adding sensors, transmitters, and other devices.

Additionally, control involves using PLCs and other devices to oversee and control industrial processes. A well-designed SCADA system with Siemens ensures accurate data acquisition and efficient control, empowering organizations to make informed decisions and optimize their operations.

Alarm and Event Management

Alarm and event management is an essential aspect of SCADA systems, especially in the context of industrial automation. Siemens uses SCADA in water treatment with a focus on managing alarms and events for smooth operations. Smart factories use Siemens SCADA solutions to monitor and track various factors in real-time. This helps to identify any issues that could impact productivity or safety.

This feature enables operators and engineers to promptly respond to alarms and take appropriate actions to mitigate potential risks. By alerting personnel through visual and audible alarms, SCADA systems enhance real-time awareness and facilitate timely decision-making. Overall, effective alarm and event management is paramount in ensuring the stability, reliability, and optimal performance of SCADA systems in industrial automation settings.

Siemens SCADA Components

One of the key components of Siemens SCADA systems is the Human-Machine Interface (HMI). The HMI SCADA serves as the user interface for operators and engineers to interact with the SCADA system. It provides real-time representation of data, allowing users to monitor and control industrial processes efficiently.

Siemens SCADA HMIs have a reputation for their user-friendly design, intuitive navigation, and custom reports. Siemens SCADA HMIs offer trend displays, alarm summaries, and historical data analyzing. These features assist users in making informed decisions and enhancing industrial operations.

HMI SCADA

The HMI Control Panel utilizes SCADA Siemens software for real-time monitoring and control. It displays critical data and allows operators to interact with industrial processes directly. SCADA enables efficient management, improving productivity and ensuring swift responses to system changes. This integration streamlines operations, enhancing overall performance and reliability.

From monitoring equipment performance to diagnosing anomalies and ensuring regulatory compliance, this system equips you for excellence.

SCADA brings forth a multitude of benefits. From improved work efficiency and enhanced data visibility to scalability and advanced security features, the advantages are both tangible and strategic.

The system supports seamless integration with a variety of industrial devices, enabling efficient data acquisition and control. The Siemens system is great at managing alarms and events. It helps operators quickly spot problems, fix them right away, and reduce downtime.