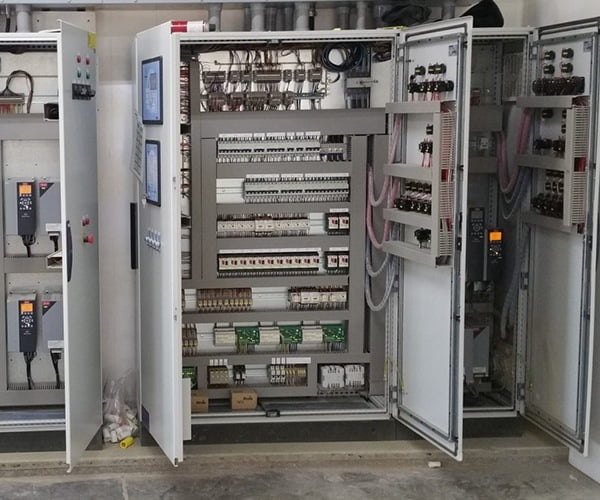

Pump control panels are a type of automation control panel specifically designed for controlling and monitoring pumps. These panels play a crucial role in the automation and efficient operation of various types of pumps, such as water pumps, industrial pumps, or sewage pumps.

Pump control panels typically include components like controllers, sensors, switches, and indicators that help regulate the functioning of the pump. The automation features allow for automatic start/stop functionality, monitoring of various parameters like pressure and flow, and protection mechanisms to prevent damage to the pump.

The use of advanced technologies such as SCADA systems and automation control panels has significantly enhanced pump control panels. This has made automation and real-time monitoring much easier.

Pump control panels control water flow and manage things like pressure, speed, and temperature. Equipped with sensors, relays, and programmable logic controllers, these panels continuously monitor the pump’s performance and respond accordingly. By automating processes and eliminating the need for constant manual intervention, pump control panels improve operational efficiency and reduce the risk of human error.

Key Features of Pump control panels

Our industrial pump control system boasts an array of cutting-edge features designed to elevate performance and streamline operations.

A. Remote Monitoring and Control

Experience the power of overseeing remote pump control panel operations from a distance. Our panels enable remote monitoring, ensuring quick response times and efficient control, even from the comfort of your office.

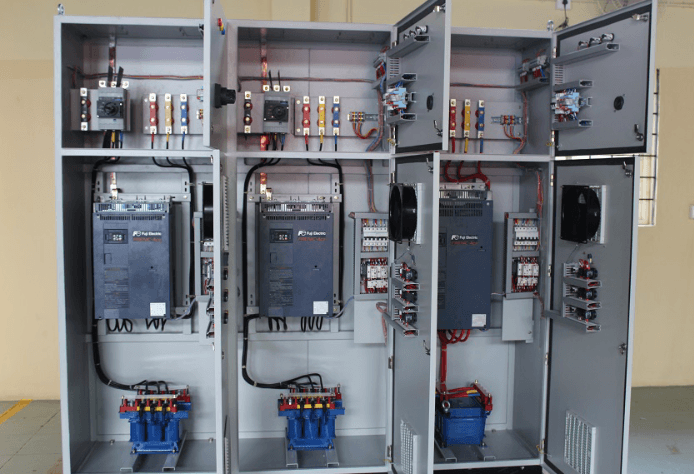

B. Variable Frequency Drives (VFDs) Integration

Harness the benefits of variable frequency drives, seamlessly integrated into our panels. This feature optimizes pump speed, enhances energy efficiency and reduces operational costs.

C. Fault Detection and Diagnostics

Prevent downtime with our advanced fault detection system. The panels provide real-time diagnostics, allowing for swift identification and resolution of issues and ensuring uninterrupted water flow.

D. Energy Efficiency

The energy-efficient design of our panels reflects our commitment to sustainability. Experience cost savings and reduced environmental impact without compromising on performance.

E. Customizable Programming

Tailor the operation of your pump system to meet your unique requirements. Our panels offer customizable programming, providing flexibility and adaptability to changing needs.

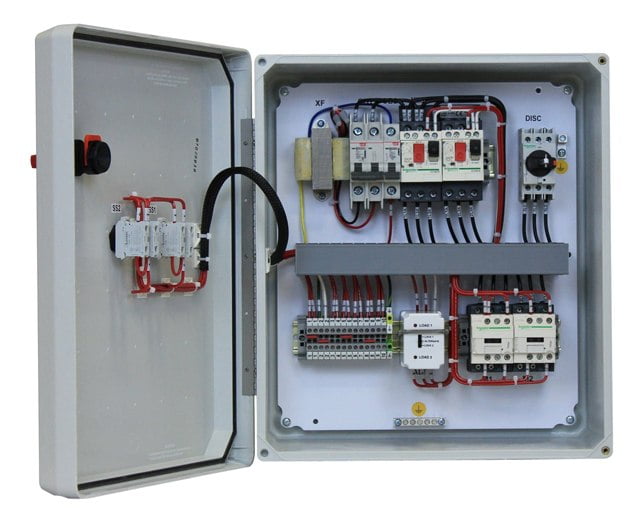

F. Weatherproof and robust design

Built to withstand the elements, our panels feature a weatherproof and robust design, ensuring durability in diverse environments.

Benefits of Pump Control Panels

Customizable Pump Control Solution:

Customizing pump control panels to control pumps is a notable advantage. Engineers can use a pump control panel to accurately set and change different settings based on project needs.

This level of customization allows for optimal control over the pumping system, ensuring efficient and reliable operation. Engineers can enhance pump performance by adjusting control settings. They can also optimize water flow, pressure, and other crucial factors. We make these adjustments to suit the specific requirements of the application.

Fault Detection in Pump Panels:

Pump control panels have advanced fault detection to monitor pump operation and detect any issues early on. These features can detect pump problems like abnormal pressure, high power usage, or strange noises using sensors and algorithms.

The control panel sends alarms or alerts when it detects a problem. The maintenance people or system operators receive these alarms or alerts to notify them. This proactive approach to fault detection enhances the reliability and longevity of the pumping system, preventing unnecessary downtime and costly repairs.

Pump Monitoring System:

In addition to fault detection, pump control panels also offer comprehensive pump monitoring capabilities. These systems monitor and provide live data on important factors like flow, pressure, temperature, and power usage.

Engineers can monitor the parameters of the pumping system to gain insights into its performance. They can quickly detect any deviations from the desired range. This helps fix problems and prevent damage or failures, keeping the pumps working well.

Energy-Efficient Pump Control:

Pump control panels play a crucial role in achieving energy efficiency in pumping systems. These panels can control pumps to use less energy without affecting performance.

The control panel can adjust variables such as pump speed, flow rates, and pressure levels to match the demand. This helps save energy by changing the pump’s output. Pump control panels can have energy-saving features like VFDs or soft starters. These features reduce power spikes when starting the pump, making it more energy efficient.

PLC Pump Control:

Many pump control panels utilize programmable logic controllers (PLCs) to facilitate advanced control and automation functions. PLCs enable engineers to create sophisticated control sequences, automate various operations, and integrate the pump control panel into larger industrial control systems.

PLC pump control panels have advantages like accurate pump control, remote monitoring, and improved fault detection abilities. The flexibility and programmability of PLCs also allow for future expansions or modifications to the pump control system, ensuring adaptability to changing system requirements.

Installation and Maintenance of Pump Control Panels

To ensure the efficient functioning of pump control panels, proper installation and regular maintenance are essential. When installing a pump control panel, it is crucial to follow the manufacturer’s guidelines and specifications.

Before installation, switch off the electricity and earth the panel. Connect all cables, including input, output, and communication cables, for devices like the Pump Controller with Modbus Communication. Appropriately label and arrange the wiring for simpler future troubleshooting and upkeep.

Once you install the pump control panel, you need to perform regular maintenance to keep it in optimal condition. This includes inspecting the panel for any signs of damage or wear, such as loose connections or corrosion. Promptly address any issues to prevent further damage or malfunctions.

Additionally, regular cleaning of the panel, including removing any dirt or debris, will ensure proper ventilation and prevent overheating. Regularly testing and measuring the water supply automation helps find and fix problems quickly.