Electrical panel installation plays a vital role in the smooth operation of industrial facilities. It encompasses a range of activities that are essential for the effective functioning of electrical systems within these operations. One of the primary tasks involved in electrical panel installation is the setup of control panels. Control panels serve as the nerve center of industrial systems, allowing operators to monitor and control various processes and equipment.

How to Install an Electrical Control Panel

Installing an electrical control panel is a critical component of electrical systems in both industrial and commercial settings. This guide will walk you through the essential steps to ensure a successful electrical control panel installation.

In addition to setting up control panels, electrical panel installation also involves the distribution of power throughout the facility. Finding optimal locations for electrical panels ensures equal power distribution to various parts and equipment in industrial operations. Calculating the investment needed for a new electrical control panel is important for budget planning. Factors like panel type, size, and labor affect the overall cost of installing a new electrical panel.

Proper power distribution is crucial for maintaining a steady and dependable power supply. Proper power distribution is necessary for the continuous operation of machinery and equipment. Proper power distribution is crucial for maintaining a steady and dependable power supply.

Wiring is important for electrical control panel installation. Engineers plan and perform wiring to ensure they correctly make all connections. They connect switches, outlets, and circuit breakers to the panel. Wiring is crucial for installing electrical panels.

Skilled electrical engineers carefully plan and execute the wiring process to ensure proper connections. They connect switches, outlets, and circuit breakers to the panel. Good Industrial Control Panel Wiring is essential for safe and efficient electricity transmission. It reduces the risk of accidents and ensures that power reaches the intended locations.

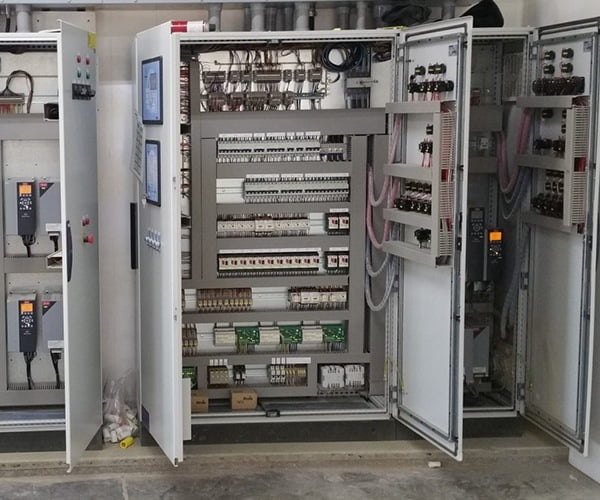

Control panel installation

Control panel installation is the foundational step in the realm of electrical panel installation. It’s akin to placing the brain of the operation, ensuring that it’s strategically positioned for easy access and optimal functionality. The professionals involved in this stage carefully install control panels, which act as the central command hubs for industrial processes. The accuracy of positioning and wiring is like tuning a musical instrument; mistakes could disrupt the whole industrial symphony.

Control Panel Commissioning

Control Panel Commissioning follows closely on the heels of installation, ensuring that all components harmonize flawlessly. This phase isn’t just about turning the power on; it’s a thorough orchestra rehearsal. Control panel commissioning involves meticulous testing and calibration to ensure that control panels meet stringent specifications. Additionally, it includes the intricate task of programming PLCs and other control systems, effectively automating industrial processes with precision.

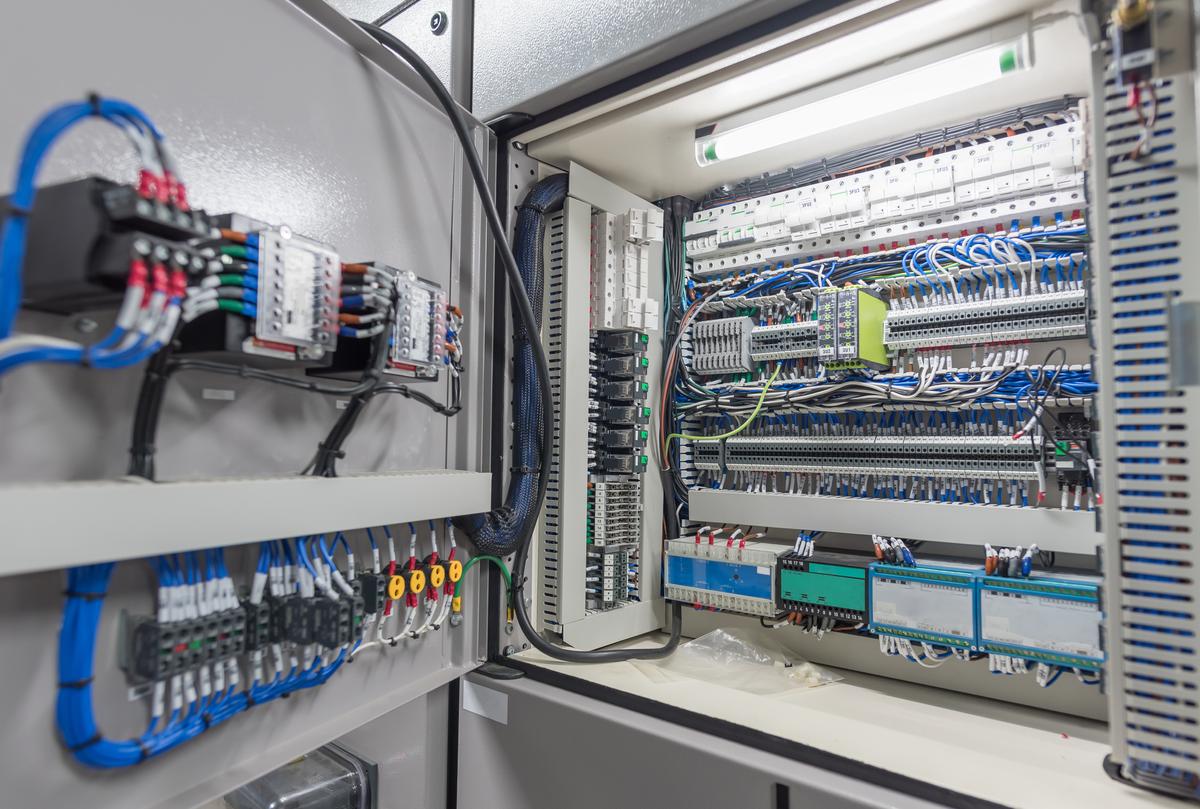

Power Distribution Panel Setup

The power distribution panel setup is important for safely and reliably distributing electrical power in an industrial facility. It is like a conductor in an orchestra, directing electricity to different parts and equipment while ensuring safety. Any mistake here could cause problems for the whole system.

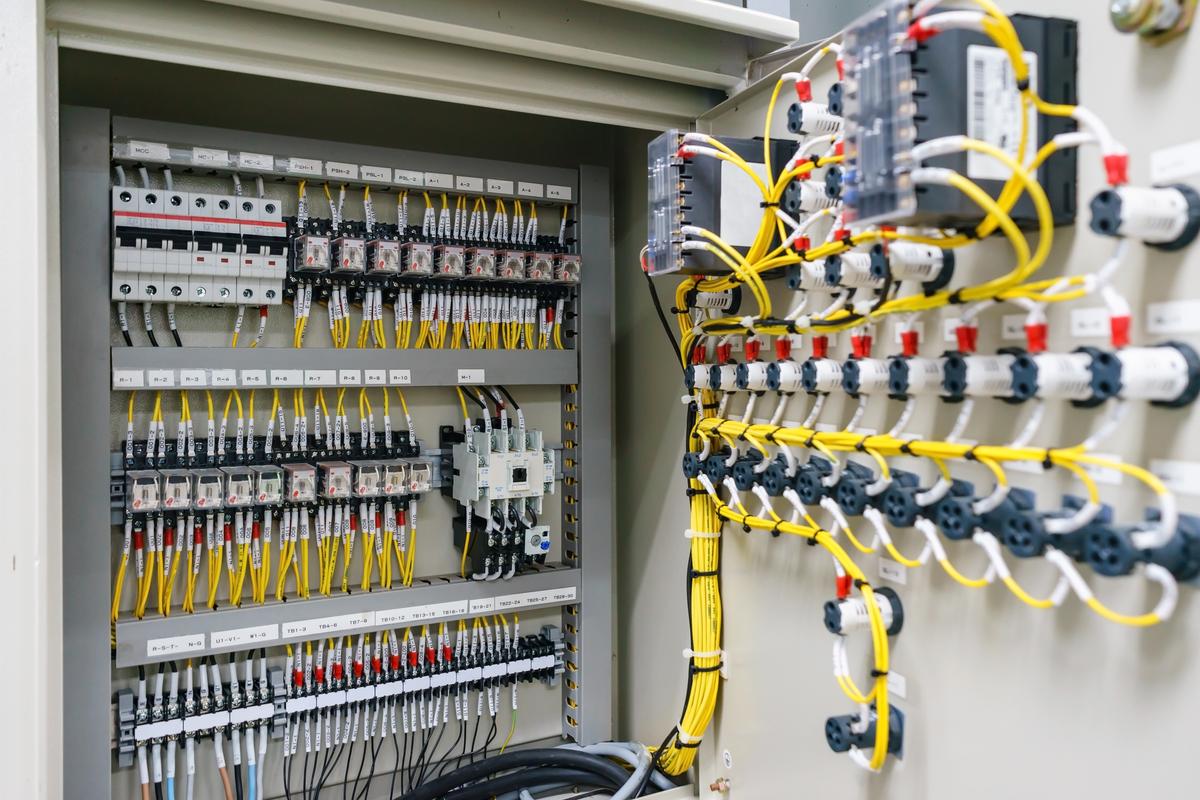

Industrial Control Panel Wiring

Industrial Control Panel Wiring is the composition of intricate electrical connections. Electrical engineers must carefully arrange connections to ensure accurate distribution of signals and power, much like a composer’s precision. Precision in wiring is not just about preventing electrical faults; it’s about creating a symphony of electrical harmony.

Control Panel Integration

Control Panel Integration is akin to the seamless coordination among orchestra sections. In an industrial facility, control panels connect to other systems and components. Control Panel Integration facilitates fluid communication between different equipment, allowing for centralized control and coordination. The result is an orchestrated performance where each instrument plays its part in perfect harmony.

Switchgear Panel Installation is responsible for protecting the electrical circuits from overcurrent. Consider it the orchestra’s protector, making sure that the energy surges don’t overwhelm any of the instruments. Proper installation is critical to preventing electrical faults and guaranteeing the safety of both personnel and equipment. The main panel sends power to subpanels in the building.

Electrical Control Panel Maintenance is the ongoing commitment to ensure that the show continues without any hitches. It involves regular inspections, cleaning, and repairs—akin to the routine tuning and maintenance of musical instruments. Proactive maintenance is essential to prevent unexpected breakdowns and reduce costly disruptions to industrial processes.

Control Panel Testing

Testing is important for electrical panel installation. After setting up and wiring, we perform thorough testing to ensure that the panel and its parts work properly. Control panel testing involves checking for problems like loose connections or faulty circuit breakers and fixing them before using the system.

Before using the system, make sure to check for loose connections or faulty circuit breakers and fix any issues. Testing helps identify any problems that may impact the safety or efficiency of the electrical system, allowing prompt repairs or adjustments.

Electrical panel installations need continuous maintenance. Regular inspections and maintenance activities are necessary to ensure that the electrical panels and associated components are in optimal condition. This involves looking for damage, cleaning parts, and doing maintenance to prevent problems from happening. Regular maintenance helps extend the lifespan of electrical panels and reduces the risk of unexpected breakdowns or malfunctions.

Electrical panel installation is important for industries. It involves setting up control panels, distributing power, wiring, testing, and maintenance. These services are necessary for the safe and efficient functioning of industrial systems.

Electrical engineers who specialize in panel installation are important for industrial facilities. They ensure continuous power supply, reduce electrical risks, and improve productivity.