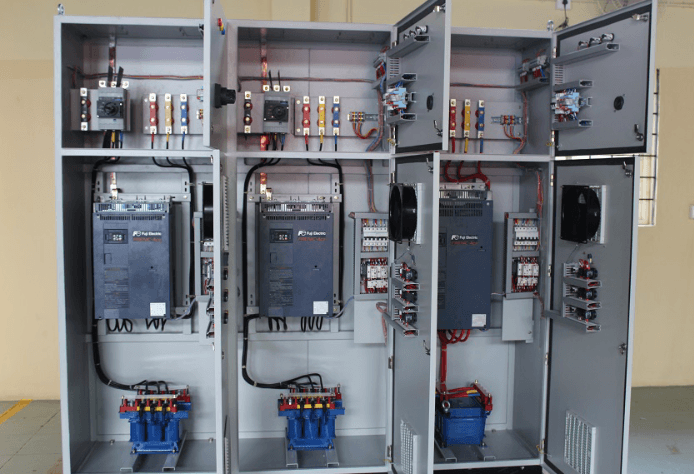

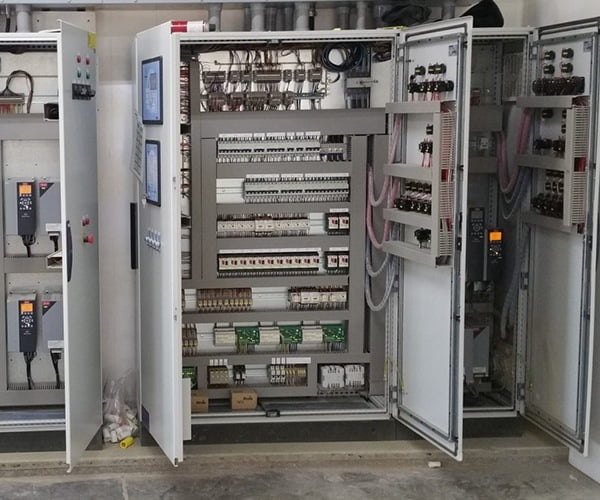

A PLC control panel is a specialized electronic device used in industrial automation to control machinery and processes. It consists of various components integrated into a single unit, allowing for the centralized management of automation tasks.

As a renowned PLC control panel manufacturer, we bring extensive expertise to our clients. Our focus lies in plc control panel design that epitomize simplicity and efficiency. The user-friendly interface of these panels empowers your workforce to seamlessly navigate intricate operations.

How PLC Control Panels Work:

PLC control panels use a specific order to handle input signals and create output signals according to present instructions. The PLC checks input signals, stores data, and follows programmed logic to create output signals.

We customize our Automation Control Panels to meet your needs in manufacturing, energy management, or process optimization. Optimize operations with our expertise in custom control panel fabrication. Tailor-made solutions for efficient PLC control panel systems, ensuring seamless automation

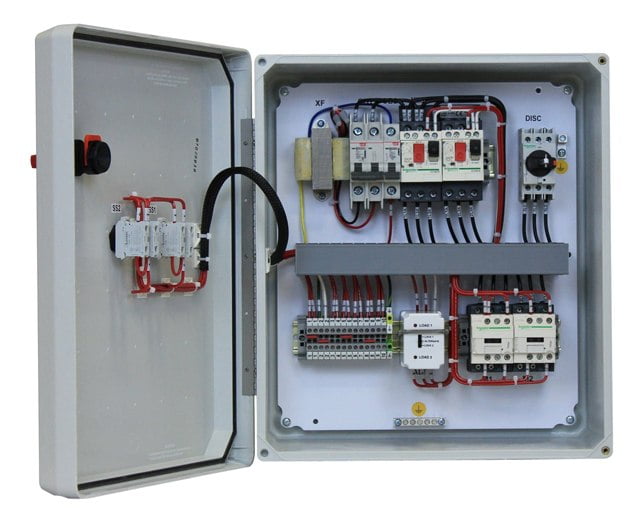

Components of a PLC Control Panel:

- PLC (Programmable Logic Controller): The PLC is a tough computer that controls things based on programmed logic. It’s the main part of the control panel. It processes input signals, executes programmed instructions, and generates output signals to control connected devices.

- Input/Output Modules: These modules interface with external devices such as sensors, switches, actuators, and other equipment. They change signals from the outside world into a form that the PLC can understand and use.

- Power Supply: Provides electricity to control panel parts, ensuring PLC and other devices operate smoothly.

- HMI: A user-friendly interface for operators to interact with the PLC control panel. It usually has a screen or keypad for users to check system status, give commands, and see process data.

- Communication Modules: These modules enable communication between the control panel for plc and external devices, networks, or systems. They support various communication protocols such as Ethernet, Profibus, Modbus, and DeviceNet, enables data exchange and remote monitoring/control.

Applications in Various Industries:

Various industries use programmable logic controller control panel. These industries include manufacturing, automotive, pharmaceuticals, food and beverage, oil and gas, and utilities. The control panels help with tasks such as process control, machine automation, material handling, robotics, and building automation. They assist with tasks such as process control, machine automation, material handling, robotics, and building automation.

PLC control panels are important for improving efficiency, safety, and productivity in various industries. They control conveyor belts and regulate temperature and humidity levels in climate control systems.

Our determined commitment to innovation and excellence solidifies our position as the preferred partner for industrial control solutions. We understand these panels’ critical role in enhancing work efficiency and maintaining a competitive edge.

When you buy our PLC Smart Control Panels, you’re getting a modern way to control industrial processes. We have lots of experience and focus on new ideas. Count on us for dependable industrial control systems. Be confident about the future.

How to install a PLC Control Panels?

PLC control panel installation involves mounting, wiring, powering on, testing, and following safety rules for a safe installation.

Pre-installation Preparations:

- Conduct a thorough site inspection to assess the installation environment, identify potential hazards, and ensure compliance with safety regulations.

- Obtain necessary permits and approvals from relevant authorities before commencing installation activities.

Site Inspection:

- Evaluate the physical layout of the installation site, including available space, ventilation, and proximity to electrical power sources and equipment.

- Think about the environment, such as temperature, moisture, dust, and corrosive substances. These factors can impact the performance and lifespan of the PLC industrial control panel.

Electrical Wiring Considerations:

- Create the electrical plc control panel wiring plan using the schematic design. Make sure to route cables correctly. Separate power and signal cables. Follow electrical codes and standards.

- Select appropriate wiring materials, gauges, and insulation ratings to accommodate current requirements, voltage levels, and environmental conditions.

We create PLC control panels that are easy to use and efficient. The panels have a user-friendly interface. This interface helps your employees navigate complex operations with ease.

Whether it’s manufacturing, energy management, or process optimization, our PLC Automation Control Panel adapts to your needs. Our commitment to innovation and excellence makes us your go-to partner for industrial control solutions.