What is Automation Control Panel?

Automation Control Panel is systems that monitor and control large machinery and industrial processes. These panels serve as a central hub for managing various components and functions within a production or automation system. Control Panels help manage and regulate processes and operations, ensuring good performance and productivity.

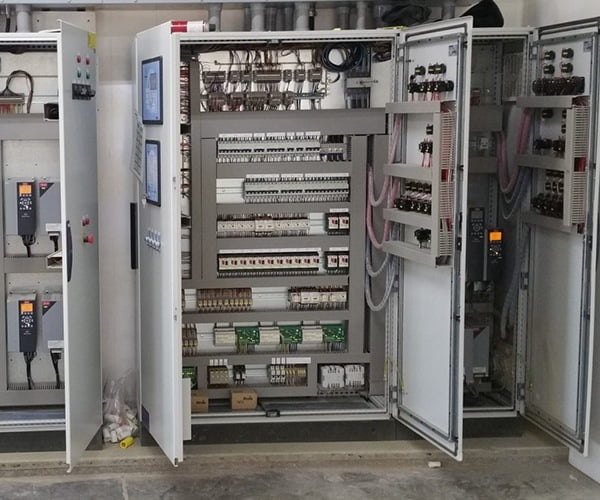

Industrial automation panel design, ensure safety, and allow operators to interact with and monitor machinery. Control panels use relays, timers, sensors, starters, and controllers to manage machinery in industrial facilities.

Explore top-notch Custom Control Panel Fabrication at Unicorn Global Automations. Our expert solutions empower your systems with efficient industrial control panels. Automation control panel design usually consist of a plc control panel, an HMI, and various components.

These components include sensors, relays, timers, starters, and controllers. The PLC is the main part of the system.

Efficient control panel wiring ensures seamless control panel integration of components. Skilled technicians use best practices to connect electrical elements, improving performance and reliability in control panels.

It processes data, makes decisions, and controls machinery using user-defined logic. The touch panel control system with HMI control panels has a screen that is easy for operators to use. They can check the machine status, give commands, and receive instant feedback.

Find top-quality automated panel systems from Unicorn Global Automations, a trusted manufacturer known for accuracy and dependability. Enhance your industrial operations with advanced Siemens SCADA integration and control panel production.

As pioneers among automation panel manufacturers, we ensure optimal functionality for diverse industries. Trust Unicorn Global Automations to integrate control panels for industry, ensuring efficiency and performance. Start innovating with our advanced solutions for custom designed industrial control panels. Upgrade your operations confidently with our excellent automation control panel technology.

Features Of Control Panels

Automation control panels boast essential features pivotal for efficient industrial operations:

- Monitoring and Control: These panels oversee heavy-duty machinery in industrial and commercial applications, ensuring seamless automation.

- Equipped with relays, timers, sensors, starters, and controllers, they handle a spectrum of processes, from simple to complex.

- Enhanced Control: Offering precise control over industrial equipment, they facilitate a hands-free approach for optimal efficiency.

- Flexibility: Automation control panels adapt to varying operational needs, promoting flexibility in system configurations.

Automation control panels are important for monitoring, controlling, and optimizing production machinery at a higher level. Control panels improves efficiency, reducing downtime, enhancing safety, and helping manufacturers meet their production goals. They also distribute power to different parts of the machinery, which saves energy and money.

One of the key functions of automation process control is to perform both simple and complex tasks. Seamlessly combining components such as relays, timers, sensors, starters, and controllers achieves this. Consequently, these integrated elements work together to automate and streamline processes, significantly reducing the need for manual intervention and, in turn, enhancing overall efficiency.

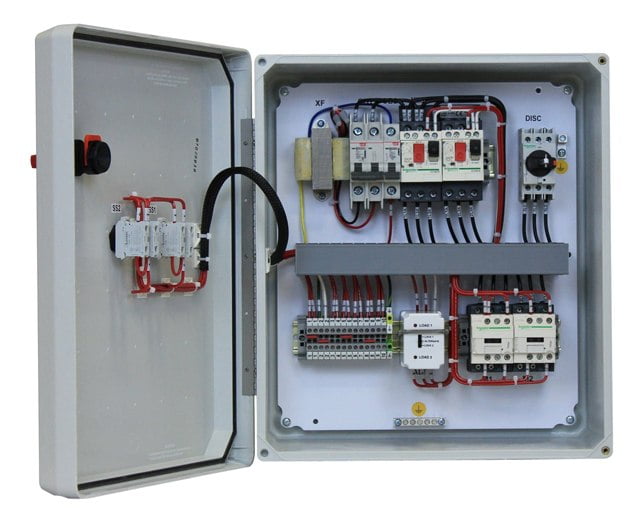

Relays are switches that control electricity flow in machines, allowing the control panels to direct power to various parts. They are responsible for activating or deactivating specific functions based on predetermined conditions or signals received from sensors.

Timers are another crucial component of automation control panels. They enable the control panel to schedule and regulate specific operations at predetermined intervals. This ensures timely and efficient completion of tasks, boosting productivity and minimizing downtime.

Sensors measure temperature, pressure, level, and flow. They give real-time data to the control panel. The control panel can then make smart choices and adjustments based on the current situation. This helps the control panel keep things running smoothly and avoid any problems or breakdowns.

Types Of Automation Panels

PLC Control Panels

A PLC control panel is a special device used in industry to control and monitor machines and processes. It has a PLC, which is a computer used in industries. It has input/output modules, communication modules, power supplies, and a human-machine interface (HMI).

The control panel follows instructions from sensors and devices to perform specific tasks. It plays a crucial role in automating and optimizing industrial processes, ranging from manufacturing to energy production. The flexibility and programmability of PLCs make them essential for a wide range of applications in industrial automation.

PLC Controllers are the brains of the automation control panel. They get information from sensors and other parts, analyse it, and perform actions based on set rules or programming. Controllers do math, make choices, and adjust settings to make machines work better and more efficiently.

PLC Control panels are an extremely efficient and reliable type of control panel. automation process control provide higher-level monitoring and control of the various functions of production machinery. They allow manufacturers to define, organize, and meet production objectives. Industrial automation control panel can distribute large amounts of power between several components of the distribution system.

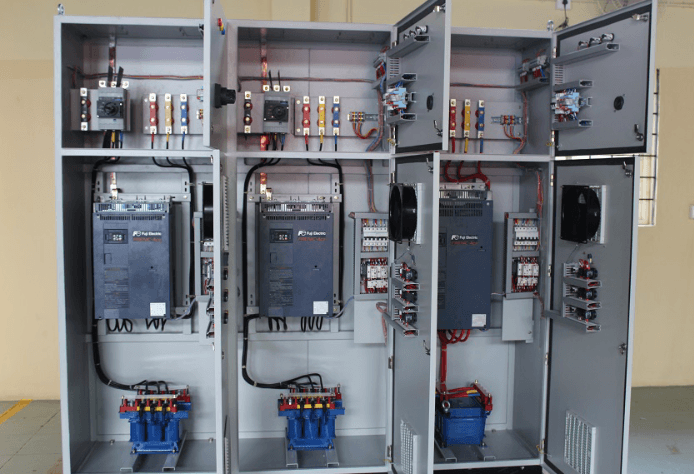

VFD Control Panel

A VFD Control Panel is an electrical panel used to control and operate electric motors with variable frequency drives. The VFD controls the speed and power of an electric motor by changing the frequency and voltage it receives.

VFD Control Panels regulate motor speed in industries like HVAC, pumps, fans, and conveyors. The VFD control panel saves energy, improves process control, and reduces motor wear. It does this by adjusting speed based on load needs. This l

Factors to Consider When Choosing Automation Panels

Automation control panels have HMI control panels for users to interact with the system easily. These panels display live data, allow for adjustments, and provide important information for monitoring processes in various industries. HMI control panels streamline the operation of electrical control panel automation by offering user-friendly functionalities that enhance efficiency and productivity.

Considering automation control panel assembly services, ensure they offer expertise in panel design, wiring, and component integration. Find providers who have a track record of offering high-quality, customized solutions that cater to your requirements. This will guarantee seamless operation and optimal performance for your control panels.

When selecting automated control systems, it’s important to consider factors for best performance and efficiency. Firstly, assess the specific requirements of the automation process, including input/output (I/O) points, communication protocols, and scalability. Secondly, prioritize reliability and durability by opting for components from reputable manufacturers known for their quality stan

Check the user interface to ensure operators can easily monitor and control processes. Smooth operations are important for efficiency. Cost-effectiveness is another crucial aspect, balancing upfront expenses with long-term savings and ROI.

Think about where you will put the control panels and pick ones with the correct IP ratings for lasting quality. Lastly, prioritize safety features and compliance with industry regulations to mitigate risks and ensure a secure working environment.